(Please note that to access the documents cited in this section, you must login into your account, then the LIBRARY Menu on top will be displayed. If you want an account, please select a web subscription option)

From the outset of the first publication of the International Performance Measurement and Verification Protocol (IPMVP®), the objective of its originators was to develop a consensus approach to measuring and verifying efficiency investments to facilitate a scaled-up global engagement into energy efficiency.

From the outset of the first publication of the International Performance Measurement and Verification Protocol (IPMVP®), the objective of its originators was to develop a consensus approach to measuring and verifying efficiency investments to facilitate a scaled-up global engagement into energy efficiency.

The purpose of the IPMVP is to reduce barriers to the energy and water efficiency industries. Adopted broadly by energy services companies initially, the IPMVP is now used by utilities and government agencies for their demand-side management incentive programs and by building, manufacturing, and industrial managers to assess and improve their facilities’ performances. Increasingly, financial institutions understand the advantages of using the IPMVP as a risk reduction framework for their investments.

In the context of the global energy transition to a low carbon economy, the IPMVP also offers a consistent approach to measuring and verifying carbon emissions reduction in a broad range of energy sectors, including different types of facilities, industrial applications as well as renewable energy.

As primarily a non-prescriptive framework, the IPMVP provides an overview of M&V's current best practices while remaining flexible. It is also a living document whose methodologies and procedures enable the protocol to evolve and reflect current and new market needs.

The IPMVP is owned and maintained by Efficiency Valuation Organization (EVO®) is a non-profit organization whose products and services help people engineer and invest in energy efficiency projects. EVO's vision is to create a world that has confidence in energy efficiency as a reliable and sustainable energy resource. EVO's mission is to ensure that the savings and impact of energy efficiency and sustainability projects are accurately measured and verified.

EVO is the only organization globally with the exclusive focus on measurement and verification (M&V). EVO’s activities span over three important fields: M&V protocol development, M&V training and education programs, and certification of industry professionals. To accomplish its mission, and vision, EVO relies on the vast knowledge and expertise of an international team of over one hundred M&V practitioners and instructors.

SCOPE

The guidance provided throughout this document is focused on “energy savings” and can also be applied to demand, water consumption, related cost savings, emission reductions, or any other quantities being measured and verified. M&V is fundamental to energy efficiency financing, energy performance contracting, energy performance management, GHG accounting efforts, and many government and utility programs.

IPMVP provides a framework that is used to:

1) verify a project has the potential to perform and save energy, and

2) quantify site-level energy and cost impacts from a targeted project.

Both components are essential to the measurement and verification (M&V) of savings.

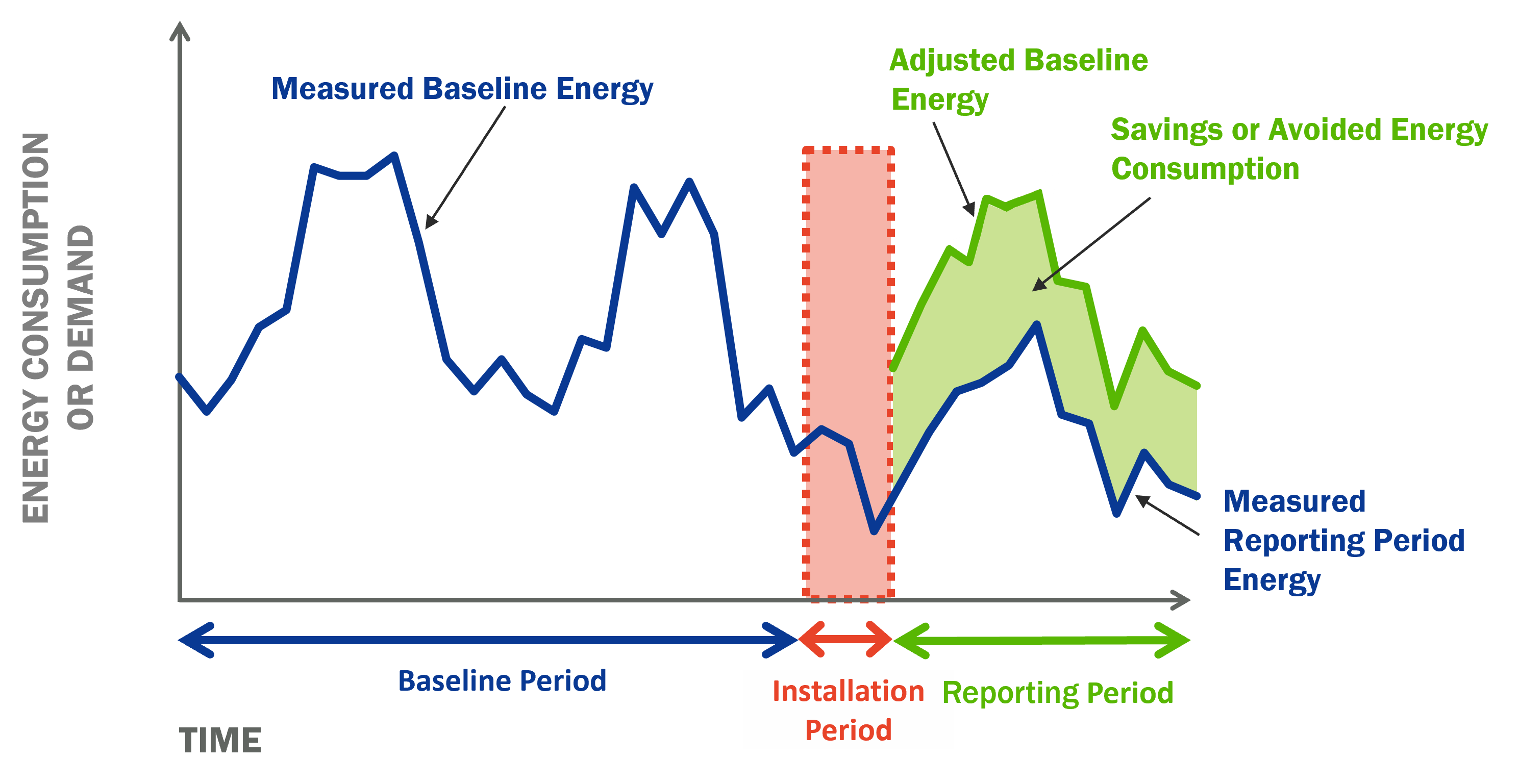

Energy savings in a facility cannot be directly measured because savings represent the absence of consumption or demand. Instead, savings are based on measurements of each fuel type or energy source impacted within a given measurement boundary before and after implementing a project, making suitable adjustments for changes in conditions.

IPMVP presents common principles and terms widely accepted as fundamental to any good M&V process. It does not define the M&V activities for all applications. Each project must be individually designed to suit the needs of all stakeholders in the reporting of energy or water savings. This individual design is recorded in the project’s M&V Plan, and savings are reported as defined therein. Using the IPMVP’s principles, framework, terms, and process to determine and report verified energy savings, facilitates reliable and translatable results.

FRAMEWORK

Energy, demand, water, greenhouse gas emissions, or other savings in a facility cannot be directly measured because savings represent the absence of energy/water consumption or demand. Instead, savings are determined by comparing measured energy consumption or demand before and after implementation of an energy efficiency measure (EEM), making suitable adjustments for changes in conditions. The comparison of before and after energy consumption or demand must be made on a consistent basis

MEASUREMENT BOUNDARY

Savings may be determined for an entire facility or a portion of a facility, depending upon the characteristics of the EEM(s) and the purpose of the reporting.

The measurement boundary is used to isolate the equipment and related energy use which are impacted by the EEM(s) from those unaffected by the EEM(s). All energy used or generated within the boundary must be measured or estimated using meters at the measurement boundary. Note that energy flows from all energy sources crossing the measurement boundary should be evaluated, and those impacted by the EEM must be measured. Note that in some cases, such as on-site solar generation, energy may flow in reverse.

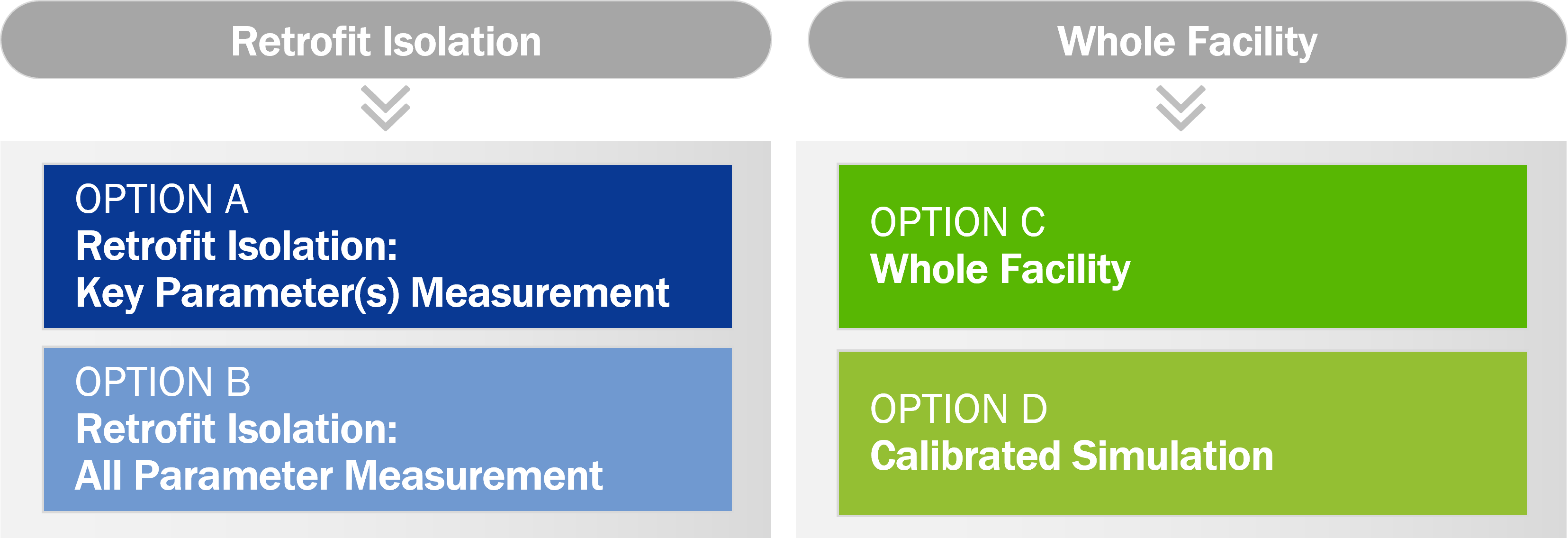

The type of measurement boundary selected generally aligns with one or more of the four IPMVP Options, shown below, and impacts the granularity of the savings reported and the measurements required. The purpose(s) of the M&V reporting must be considered when selecting an Option.

If the purpose of reporting is to verify the savings from equipment affected by the energy efficiency project, a measurement boundary should be drawn around that equipment, and measurement requirements for the equipment within the boundary can then be determined. Energy consumption and/or demand may be directly measured or determined by direct measurement of key variables that can be reliably used to calculate demand or energy consumption. The approach used is a Retrofit Isolation Option (Option A or B)

If the purpose of reporting is to verify and/or help manage total facility energy performance or verify the savings from multiple EEMs with interactive effects, the meters measuring the supply of energy to the whole facility can be used to assess performance and savings. The measurement boundary, in this case, encompasses the whole facility. The approach used is Option C: Whole Facility.

If the Baseline Period or Reporting Period data are unreliable or unavailable (e.g., new construction), energy data from a calibrated simulation model can be applied for either a portion or all of the facility. The measurement boundary can be drawn accordingly. The approach used is Option D: Calibrated Simulation.