![]() By Paul Calberg-Ellen *

By Paul Calberg-Ellen *

1. Introduction

The "MPEB" R&D project ran from 2018 to 2021. It brought together many actors in the field of energy performance of buildings, in France. It involved design offices, ESCOs, research laboratories, etc. What was the purpose of this project? It was to take stock of existing knowledge on measuring the energy performance of buildings, to highlight good practices, and to propose tools for users of energy performance measurement. In addition to these objectives, one of the important outcomes of this project is the perspective it has provided on certain concepts, particularly in terms of Measurement and Verification.

More than a year after the official end of the project - and after some additional time of exchange and reflection within EVO working groups, as well as practical application on M&V missions - this article offers the reader a certain look at M&V concepts. Which, while relying on the fundamentals of the International Performance Measurement and Verification Protocol (IPMVP), seems to us to enrich it, in particular by opening up its framework of use even more broadly than it is currently.

2. From the determination of measured savings to the determination of measured energy performance

2.1 Definition of energy performance

In order to determine the energy performance of a car or a piece of HVAC equipment, it will certainly seem natural to the reader to say that it is necessary to specify the set of conditions used to carry out the performance test.

It is easy to see that judging the performance of two cars by comparing the fuel consumption of one car on a motorway, with the fuel consumption of another car on a city journey is of little interest. This has led to the standardisation of test procedures for this type of equipment, which correspond to the use, in the laboratory, of sets of 'given', standardised conditions. This makes it possible to obtain comparable results between two pieces of equipment, or on the same piece of equipment evaluated at different times in its life, for example.

In the field of buildings, it is difficult to test an entire building in the laboratory, and it is all the more unrealistic if there is no, or only marginal, mass production, as is the case for the examples above. It would mean testing each building one by one in a laboratory to assess its performance, under a set of controlled conditions: unthinkable.

However, the definition of energy performance should be the same for cars or climate equipment. Energy performance is energy consumption under "given" conditions. This is the definition we have chosen for the MPEB project.

It should be noted that this definition is entirely consistent with the leading practice of energy performance assessment in the building sector in France, within the framework of the regulations: an assessment based on a calculation engine, which makes assumptions in terms of the use of the building and the environmental conditions (weather in particular).

However, what we are interested in here is not the energy performance evaluated "a priori", but the energy performance evaluated from measurements.

2.2 Evaluation of the measured energy performance

If it is not possible to assess the energy performance of a building by testing it in the laboratory, how can the energy performance be assessed?

The practice at the heart of M&V, adjustment, gives us the key: it is enough to perform a adjustment operation. If it is not possible to place oneself in controlled conditions, as in the laboratory, the adjustment makes it possible, via the use of a mathematical model (a set of more or less complex calculations), to estimate the energy performance of a building, in "given" conditions, based on consumption measured under any conditions. However, certain conditions for the validity of the model will have to be checked and, let's say it right away, the evaluation of the measured energy performance will thus not be possible for a certain number of cases.

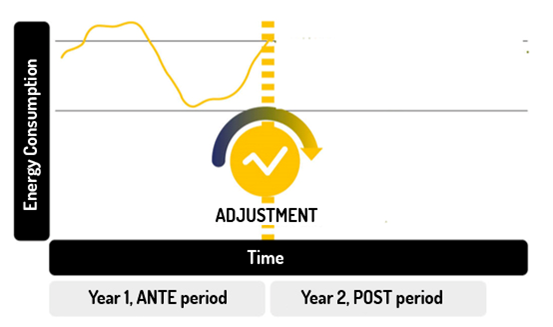

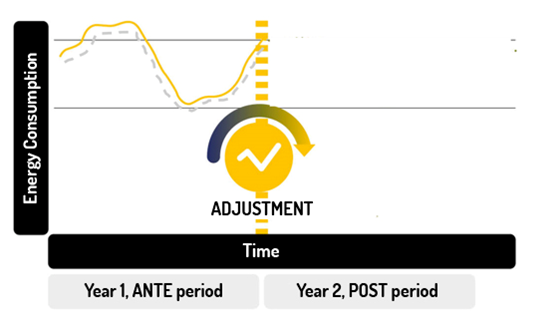

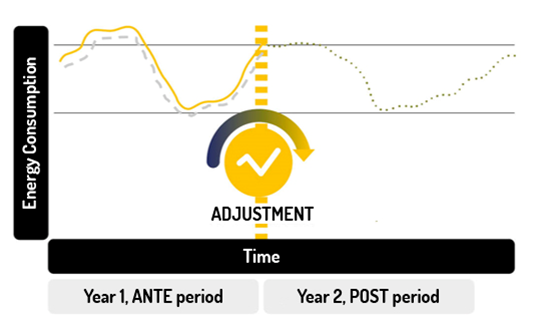

Starting from an energy consumption measured on a building...

...building a model of this consumption...

... can be used to estimate what the consumption would have been under different "given" conditions, here the conditions of the POST period. We will call this consumption evaluated under "given" conditions a performance. In other words, using the usual IPMVP vocabulary, a measured energy performance is an adjusted energy consumption.

Source diagrams: MPEB project

Those familiar with M&V will recognise in the above diagrams the first steps of the classical process of evaluating measured energy savings, through the determination of an adjusted consumption. Indeed, if the adjusted energy consumption is compared to the actual measured consumption, an evaluation of the energy saving is obtained, independently of the given conditions considered for the project.

In order to evaluate the interest of this slight step from a classical M&V approach focusing on the concept of energy saving to an approach generalising the interest of the adjustment to the evaluation of the energy performance, let us continue to develop some concepts...

3. Generalisation of adjustment methods

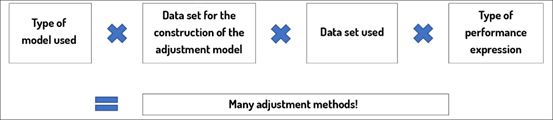

We propose to define the adjustment methods on the basis of four criteria:

• The type of model used

• The data set used to build the fitting model

• The set of data conditions used

• The type of performance expression.

Let us now detail these four criteria...

3.1 Type of model used

Several major families of models can be used to carry out adjustments. It is interesting to distinguish the families that will involve specific processes, particularly in terms of validation.

We therefore propose to distinguish between

- Statistical adjustment models

- Physical adjustment models (thermal/energetic simulation)

- Hybrid adjustment models

- Adjustment models by simple decomposition of consumption.

3.2 Data set used to build the fitting model

The adjustment model must necessarily be built on measured consumption data, if one wants to be in the field of measured energy performance. In order to use a systematic approach to the qualification of the period on which the model is built, while being consistent with the approaches usually used in the IPMVP framework, we propose to adopt the names ANTE (preferred to "reference") and POST (preferred to "reporting"). These names are well suited to cases of renovation/energy performance improvement actions. In the case of new buildings, or in the context of long term performance monitoring, the terms will have to be adapted on a case-by-case basis, but the concepts remain valid.

An adjustment model can be built from real, measured data, which are therefore either from the ANTE or the POST period.

3.3 Set of data conditions used

The adjustment model is used to estimate what the energy consumption would have been under conditions different from the conditions encountered for the measurement. These conditions can be either:

- The conditions of the ANTE period

- POST period conditions

- Normalised conditions: the term normalised conditions refers here to conditions whose values have been defined conventionally. The conditions could be meteorological conditions, occupancy, etc.. Note here that the ANTE and POST conditions are only particular sets of standard conditions...

3.4 The type of performance expression

Performance can be expressed:

- In differential form, i.e. by comparison with a reference value: this is the case when we reason in terms of energy saving. Two energy consumptions are compared, one being used as a standard against which the other is compared, in order to establish the variation, the differential. It is also common to express this differential as a ratio of a benchmark value (typically when expressing a saving as a percentage of the “baseline”);

- As an absolute performance. In this case, it is simply a consumption value, expressed under "given" conditions (a priori different from the conditions actually encountered).

3.5 A large number of adjustment methods, as many solutions to the different configurations encountered in the field

The combination of the different adjustment criteria gives rise to numerous possibilities for determining the measured energy performance.

These methods of determining the measured energy performance all have two things in common:

- They are based on the notion of adjustment, the objective of which is to estimate what the measured consumption would have been in conditions different from those encountered for the measurement, (the adjustment plays the role of a sort of virtual laboratory, recreating controlled conditions by calculation)

- The adjustment is carried out thanks to a model built on measurement data.

We will see in a forthcoming article how this approach both corresponds well to the usual approaches proposed by the IPMVP, but also how it makes it possible to propose solutions to certain configurations for which it was difficult or impossible to find an IPMVP option corresponding to the case encountered.

![]()

(*) Paul Calberg-Ellen is Director at APEBI