By Alex Rathmell*

The Investor Confidence Project (ICP) is an international project to reduce performance risks and due diligence costs through the standardisation of energy efficiency project development. Under the ICP’s Investor Ready Energy Efficiency (IREE™) system, project developers, who have to be highly qualified and experienced, develop projects following the ICP’s protocols which are then independently reviewed by an ICP Quality Assurance professional. Projects that receive the IREE certification have followed international, transparent best practice and therefore will have lower performance risk and financial institutions can spend less on due diligence – lenders and investors, as well as CFOs, can have more confidence in the predicted energy and cost savings. They also have on-going Operations & Maintenance and Measurement & Verification plans, both of which help to maintain savings through the life of the project.

ICP already has well-used protocols for the buildings sector, both commercial buildings and apartment blocks in the US and Europe. New protocols for energy efficient street lighting and industrial energy efficiency projects - which includes upgrades to existing district energy systems - have recently been developed in Europe with the support of the European Commission’s Horizon 2020 programme. They were created by an experienced pan-European technical team, with extensive industry consultation through focus groups and technical forums built in to the development process. This article looks at how the IPMVP has provided a platform for the IREE system, and discusses some of the decisions and trade-offs made by the technical team in developing the new protocols.

The new protocols mirror the structure of the existing ICP buildings protocols, and this consistency across the entire IREE system is essential. ICP is in the business of defining good practice in delivering energy efficiency, and project developers need to become familiar with the protocols’ structure, inputs and outputs, gearing their own systems and processes around their requirements. Sometimes the IREE system challenges established industry practice, requiring developers to follow an iterative, evidence-based and rigorously measured approach that delivers a genuinely investment grade project in which investors can have confidence (hence the name.) Yet the technical authoring team are always conscious that projects take place in the real world with all its attendant constraints, and so the new industrial and street lighting protocols include major adaptations for these different contexts. More on that shortly.

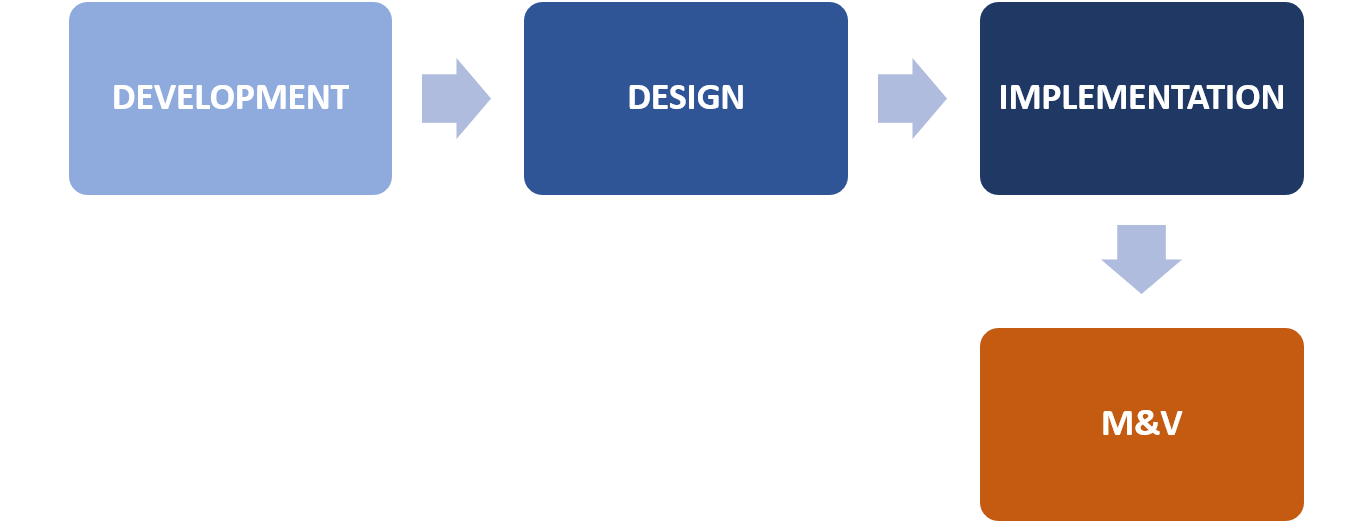

All the protocols rely on the IPMVP as a key underpinning reference document, and it is striking how much of the discipline of executing a high quality energy efficiency project is already contained in the IPMVP, whether in the letter, or simply in the spirit of the document’s principles-based approach. Perhaps the most stark example is the sequence of stages in an energy efficiency project. Many definitions of project development go like this:

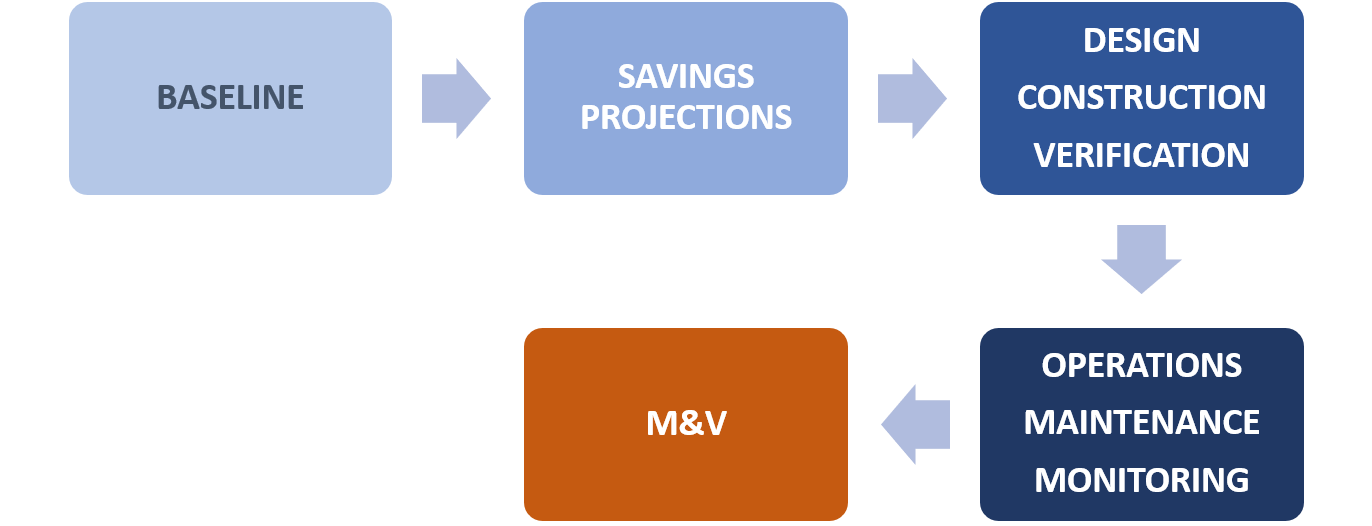

M&V in this structure is essentially an afterthought. Often a tokenistic M&V Plan - typically patchily-populated document with subheadings taken from the IPMVP - is produced prior to implementation of ECMs. But the ‘meat’ of the M&V activity, if it happens at all, is consigned to the post-implementation phase. This has the obvious downsides, at least for the host and any investors, of making underperformance difficult to identify and rectify, and uncertainty as to whether performance risk has meaningfully been transferred. In the IREE system, meanwhile, the sequence is like this:

The IREE system moves the bulk of the M&V activity up-front to the baselining stage. This approach means that the same baseline is used to both estimate and ultimately evaluate the savings, ensuring that M&V is integral to the way the project is conceived, developed, executed and proven. There is minimal risk that, for example, the project will be executed without adequate metering and monitoring systems, and ultimately, a project that does not have a complete, specific, IPMVP-adherent M&V Plan cannot be certified ‘Investor Ready’. For the technical authoring team, writing the baselining stage of the new ICP protocols was the most challenging and time-consuming part of the process. In comparison, the ‘M&V’ stage - in reality the post-retrofit calculation of savings according to the certified M&V Plan - was straightforward and largely wrote itself, hopefully mirroring the experience of practitioners using the protocols in the real world.

Industrial energy efficiency and street lighting projects present very different M&V challenges. For each, the authoring team had to strike a balance between three factors:

- Theoretical elegance, setting high standards and defining best practice

- Practicality of implementation, bearing in mind any established industry practices and constraints, particularly in different regions and countries across Europe

- Consistency with the wider ICP/IREE system

For the street lighting protocol in particular, these elements were in tension. Many street lighting systems in Europe use unmetered power supplies - energy consumption is typically deemed based on a registered database of assets. Upgrading these assets, often replacing sodium lamps with LEDs, achieves a saving by changing the contents of this database, meaning the host is billed less. This approach appears to be at odds with both the good practice defined by IPMVP and the methods used in other ICP protocols, both of which would suggest the use of measurement in the baseline and reporting period to give a sufficiently accurate evaluation of savings. The large capital investment, and the large magnitude of expected savings, should in theory permit a fairly substantial M&V budget for these projects.

On the other hand, if the new ICP protocol were to insist that the project developer install metering in a previously unmetered system purely for the purpose of demonstrating a saving from the street lighting upgrade, would this make potential adopters of the protocol less likely to use it? Any new metering would not be used for billing purposes - this would remain on a deemed basis - so the metering could be considered a direct cost of complying with the IREE system. The extra cost would ‘buy’ no additional certainty around the cost savings generated by the project, which would remain a function of the change in asset register.

The technical team ultimately decided to permit a version of deemed savings under the street lighting protocol, allowing this as an alternative to a measurement-based approach for instances where (and only where) unmetered supplies are in use. The protocol now codifies and tightens the process of calculating deemed savings - including verification through measurement that assets’ energy consumption is accurately represented by deemed values - and including both measurement-based and deemed processes allows the maximum number of street lighting projects to benefit from the protocol by reflecting the real-world practice of the street lighting industry.

For industrial energy efficiency projects, the challenges are different. Industrial facilities - examples include manufacturing sites and heavy plant used for energy centres and heat networks - are heterogeneous, and their workings may require highly specialist knowledge. Energy savings can be achieved by leveraging this specialist expertise to configure plant more efficiently or replace component parts, but a simpler route to savings may also be found by addressing the supporting equipment - building loads such as lighting and HVAC, and compressed air, pumps, fans etc.

The technical team decided early on to split the industrial protocol in two. The ‘targeted’ variant would deal with more straightforward ancillary loads and component replacements, with M&V techniques based upon IPMVP Options A and B (retrofit isolation.) The ‘complex’ variant of the protocol would provide for other project types. But how should the protocol deal with highly bespoke industrial projects that could not be meaningfully quality assured by a generalist energy efficiency practitioner? For example, a new heat recovery process in a unique manufacturing line. Should these one-off projects be permitted, or should the protocol constrain itself to non-process load, or a prescribed list of permissible ECMs?

The IPMVP ultimately provided the answer to this question. Like the IPMVP, provided the process used is robust, accurate and auditable, the ICP protocol can be ‘agnostic’ regarding the ECM itself. The complex industrial protocol has adopted the spirit of the IPMVP document - and the supporting Statistical and Uncertainty material - almost in entirety. For example, users of the protocol are required to work through the process of calculating the required level of accuracy of the M&V exercise based on the expected energy saving and the variability of the baseline data. In turn this drives the M&V method selection, baseline modelling and the deployment of metering.

The ICP industrial protocols then build on IPMVP by setting requirements for the skills and experience of the practitioners involved in both project development and quality assurance. The quality assurance provider is guided towards the principles-based approach of the IPMVP for evaluating the project, even if they have limited direct experience of the ECM(s) involved in the case of bespoke-process specific measures, an approach that allows any worthwhile energy-saving project to benefit from the enhanced discipline and accuracy required for Investor Ready certification. The result is a protocol suite that allows straightforward projects to be quickly developed, funded and deployed, and then meaningfully aggregated (through the targeted variant), and equally allows one-off custom projects to be attractive to investors, whether external or internal to the host company (through the complex variant).

There is currently a great deal of focus on the promise of M&V 2.0, metered energy efficiency and tokenised negawatts on blockchains, and there is no doubt that this is an exciting time for the future of M&V. But developing the IREE system has revealed a basic truth: most energy efficiency projects still don’t incorporate M&V as a fundamental, and those that do often treat it as an afterthought. ICP is addressing this by embedding the letter and spirit of the IPMVP in its definition of investment grade energy efficiency and making this useable for practitioners by tailoring its requirements for different contexts. In doing so, ICP is making a substantial contribution to awareness raising and capacity building around M&V, particularly in Europe where it is finally taking its place as one of the key enablers of an efficiency-first energy strategy.

Until April 2019, European project developers or hosts planning industrial or street lighting energy efficiency projects may be able to benefit from funded technical assistance from the ICP Europe technical team. The support package is intended to help project developers deliver an IREE-certified project and to align their processes to the IREE system, and includes training, a project-level gap analysis to identify development areas, and a quality assurance review of pilot project(s).

(*) Alex Rathmell CEng MBA CMVP is a consultant based in the UK and an Associate Partner at EnergyPro, a fast-growing team of experienced energy professionals working on energy system change. In 2011 Alex co-founded EEVS Insight, the UK’s largest and longest-established M&V centre of expertise, and remains an Associate at EEVS. As part of the Investor Confidence Project Europe consortium, Alex has contributed to technical authoring of new protocols for infrastructure and industry under the I3CP project.

For more information on the Investor Confidence Project in Europe, and to download the new protocols and supporting materials, visit: europe.eeperformance.org

This article borrows from Dr Steve Fawkes’ blog, Only Eleven Percent: https://www.onlyelevenpercent.com/why-financial-institutions-should-be-worried-about-energy-efficiency-performance-risk/

The ICPEU and I3CP projects have received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreements 649836 and 754056. The sole responsibility for the content of this article lies with the authors. It does not necessarily reflect the opinion of the European Union. Neither the EASME nor the European Commission are responsible for any use that may be made of the information contained therein.