By Rajvant Nijjhar*

The International Standard for Energy Management Systems, or ISO 50001 was first published in July 2011 – and is already being replaced by a 2018 version. This change was necessary to ensure that all management systems standards (MSS) adhere to the same common structure, terminology and approach. After all, ISO is a standards-making body, so there should be standardised approaches to all MSS whether it’s ISO 50001, IS0 140001 for Environmental Systems Standards, or ISO 9001 on Quality management. This is called the High Level Structure (HLS).

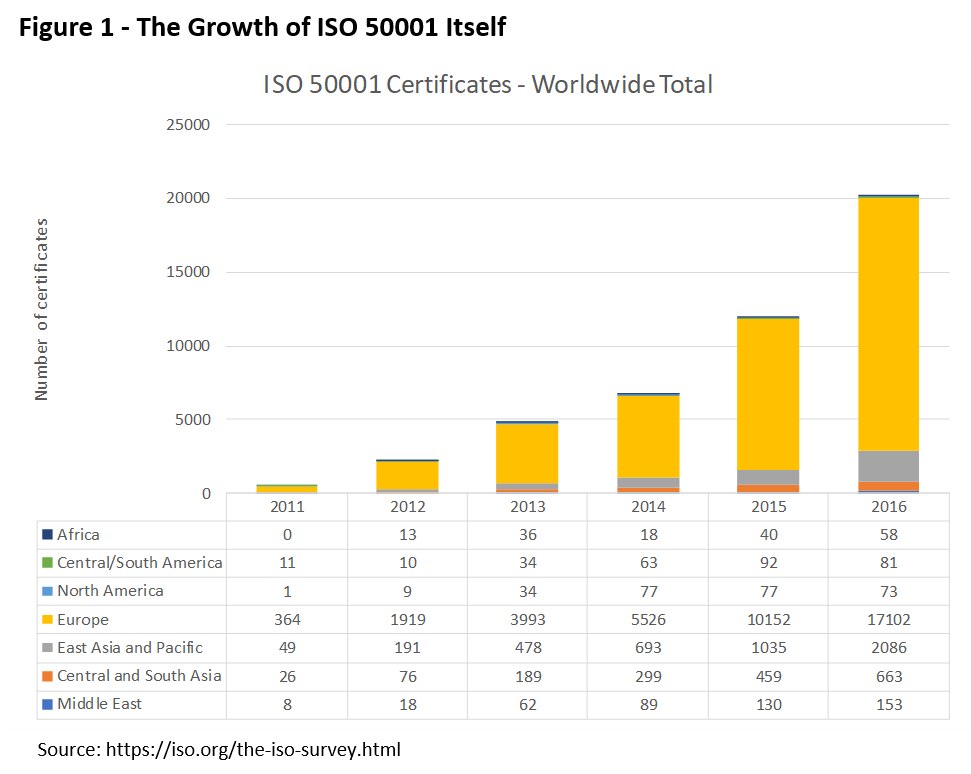

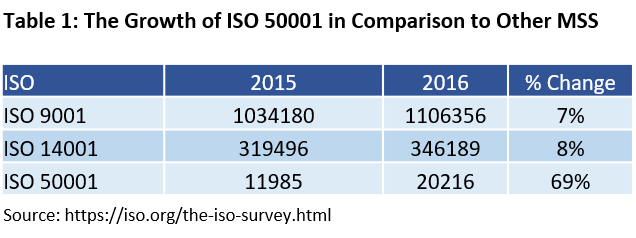

This update has hence come sooner than usual for most updates to standards. We are still trying to get to grasp with the number of copies sold, although ISO believes it has become one of their biggest selling standards. As one can self-declare to adhere to ISO 50001, as well as become externally certified, by a suitably qualified certifying body (CB), the actual numbers in implementation out in the world appear to be unknown. Unless the CBs provide information to ISO, this data is not tracked. However, from the information provided to ISO in their surveys, it is clear that compared to other MSS that ISO 50001 is indeed on an exponential growth curve. Figure 1 and Table 1 illustrate this point.

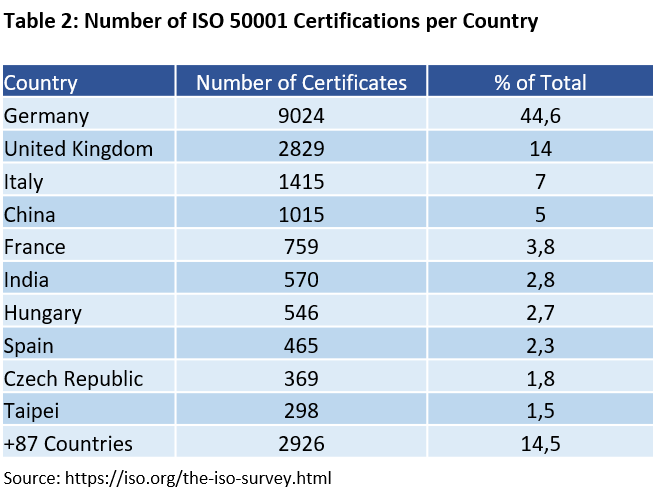

And when it comes to countries, it is clear that Germany is taking the lead due to generous government tax breaks and incentives as illustrated in Table 2.

Interestingly, the Chinese also claim to have 10,000 certifications in order to meet a National Law related to the top 10,000 energy consuming companies (not shown above). This was verbally heard at a conference attended in May 2017 – but also understood to be an adapted version of ISO 50001. I’m afraid my Chinese needs some work before I can elaborate further!

So, you are probably wondering then what’s the hype about and what is the EnMS, before I can even go onto explain what changes are in store. In short, my own definition of an EnMS is:

“A structured approach to the management of energy to enable energy improvement opportunities to be assessed and appropriate measures to be instigated and monitored on an on-going basis.”

It makes you look at your energy uses, set targets to achieve reductions in consumption or make improvements in efficiency, implement such actions or measures, then review if they have been a success. In other words, to plan, do, check, act.

Key to success and rather underrated is Top Management or Leadership commitment to provide the resources to enable this to happen. These backing and support is crucial and may mean plucking up the courage to ask your Board Level Executive for support. Their name on a Policy does carry weight in the company and therefore is seen to have equal importance to Health and Safety, Environment, Quality etc.

People often also ask, ‘’well how long will it take to implement?’’ And the short answer is between 9 to 18 months realistically. A typical process will follow as below:

- Gap Assessment – where are we when we compare ourselves to the Clauses in ISO 50001(1-2 Months typically)

- Planning to implement the EnMS – getting your teams and key people together, understanding all of your significant or large energy uses across different energy types, setting targets and looking for opportunities (3-4 Months typically)

- Implementing the EnMS, installing the hard measures, undertaking training of key personnel, measure the impact (3-4 Months typically)

- Putting the EnMS into operational practices, measuring the effectiveness of the energy performance improvement, identifying areas of general improvement and having a management review for feedback (4-8 Months typically)

It’s a systemic approach. Hence, why Top Management does need to be involved. And if you are looking to be externally certified, add on another 3-4 months for an initial audit, time to make changes, and then a final certification audit. Even though the certificate might be valid for 3 years, the CBs like to return on an annual basis to ensure that standards are being maintained in the interim.

So, when producing the updated version of ISO 50001 – the team including myself were mindful of a number of key features. Namely, that the standard was written to appeal to SMEs, and therefore the ability to self-declare, and that the EnMS was all about delivering continual energy performance improvement.1 The document did grow from 22 core pages to 34 but so did the clarity on surprisingly some fundamental issues that were noted in the short 5-year timeframe the standard has been in use.

These fundamentals included defining more clearly what was meant by energy performance improvement, given the ISO 50001 defines energy as being ‘’manner or kind of application’’ (e.g. lighting heating, ventilation) and energy performance as being ‘’energy use, energy efficiency and energy consumption’’. As there was difficulty in explaining how one can have an improvement in use without leading to either a reduction in consumption or a change in efficiency, the definition of energy performance improvement was created to be:

3.4.6

Energy performance improvement

Improvement in measurable results of energy efficiency (3.5.3), or energy consumption (3.5.2) related to energy use (3.5.4), compared to the energy baseline (3.4.7).2

Other such clarifications included the use of renewables, which are not considered to be an energy performance improvement, as you are replacing one source of energy with another.

There was also the introduction of the concept of normalisation and using relevant variables if significant. Therefore, energy performance indicators that are developed to evaluate performance against an energy baseline, can be adjusted to differences in weather, occupancy, production etc if needs be. Bearing in mind, use of the standard by SMEs – some flexibility was allowed for in this area, for example in using simplified adjustments as opposed to regression analysis, that might be a bit off-putting to an organisation of say 15 staff. For M&V purists, this might be upsetting.

There was even greater and stronger emphasis placed on the role of Top Management – partly also because of text that was compulsory to use from the HLS. Another welcome move was consideration to overall business process so that Energy Management is not seen as out on a wing on its own, but part of the bottom line profits of an organisation. So, actions to address risks and opportunities are introduced.

For M&V purists, the section on Monitoring and Evaluation has been superseded with a bigger and better section on Performance Evaluation. This does include actions necessary to collect data, the type and frequency of data, including for relevant variables and static factors. And, we cannot only evaluate energy performance but the performance of the EnMS (how good the management reviews are), even though intrinsically you cannot have one without the other. Energy Performance Improvement will result from an effective EnMS.

There was also a bit of debate on what is meant by continual improvement. Although this has always been in ISO 50001, in the scope and in section 4, with the HLS, there is a separate clause on this subject. Annex material draws various examples of improvement, recognising that in fact at some point in time, there could be a plateau. Once you have extended your scope and boundary and literally done all you can, it could be a case of simply maintaining processes, systems and equipment in order not to deteriorate performance.

All in all, the new ISO although lengthier will provide more guidance and clarification and was needed. It has taken into account, user feedback despite the shorter than usual renewal timeframe and is a more precise document. It will enable users of other MSS to pick up common themes and therefore improve understanding and implementation. For those in the midst of ISO 50001:2011, there is a 3-year transition to understand these changes and be prepared. But that’s the purpose of all MSS – to plan ahead and be prepared.

END NOTES

1. The difference between continual and continuous is that the latter is considered to be step-wise regular change whereas continual allows for some flexibility in terms of the time taken between improvement stages.

2. ISO 50001.

(*) Rajvant Nijjhar is Director of iVEES.